Our Manufacturing Facility

We're a trusted U.S. label manufacturer offering factory-direct prices and same-day shipping. From warehouses to packaging lines, we make it easy to get the labels you need — fast, affordable, and reliable.

We're a trusted U.S. label manufacturer offering factory-direct prices and same-day shipping. From warehouses to packaging lines, we make it easy to get the labels you need — fast, affordable, and reliable.

We make labels - and we make them really well. As a U.S. based manufacturer, we handle everything in-house to give you better pricing, faster turnaround, and labels you can count on. Whether you need shipping labels by the truckload or something custom, we've got you covered.

We source our facestocks and liners directly from trusted paper mills, giving us greater control over quality, cost, and availability.

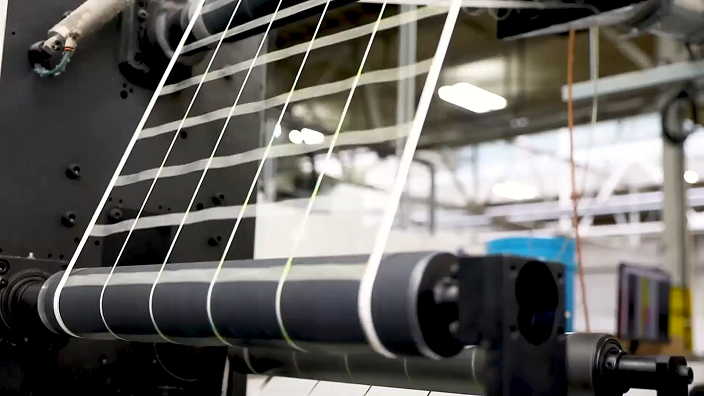

A thin layer of silicone is applied to the liner to ensure clean, consistent release of the label from its backing during application.

We make our own hot melt adhesive in-house and coat it onto the liner, allowing us to meet a wide range of application needs, including freezer-grade and removable options.

Facestock, adhesive, and liner are laminated together to create a fully constructed label material, ready for die cutting or printing.

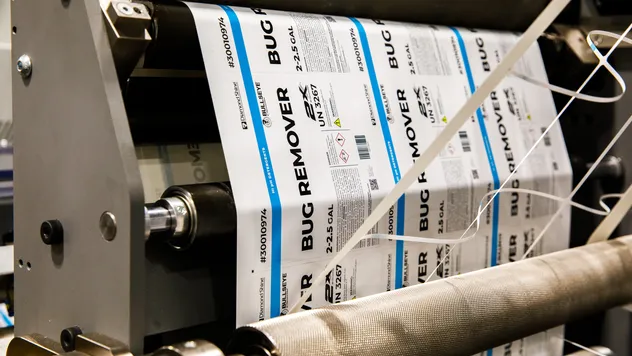

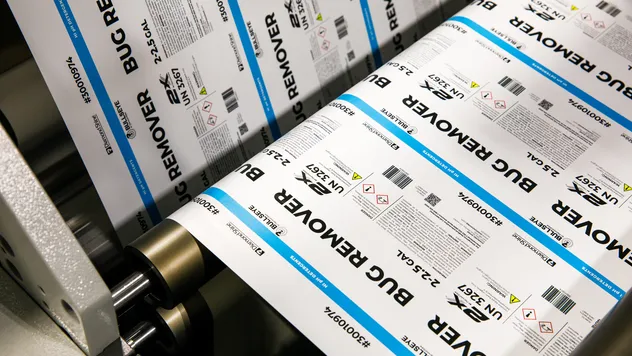

We use digital presses for vibrant, high-resolution label printing. For solid coverage or background color, we apply flood coating across the entire label surface.

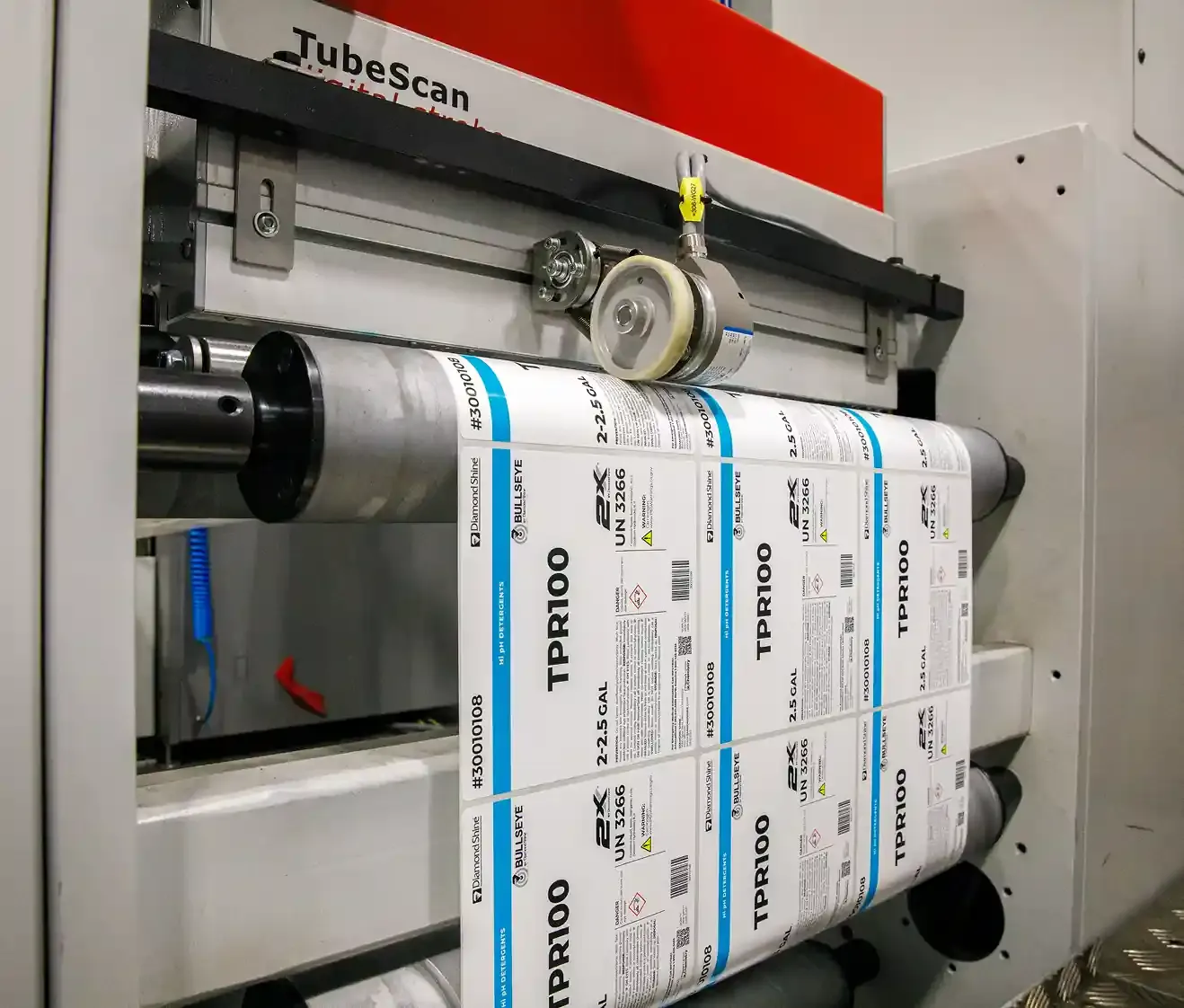

We precision-cut labels to size using custom tooling, ensuring clean edges and consistent shape— ready for rolls or fanfold formats.

Finished rolls or fanfold stacks are inspected, counted, and packaged for fast, accurate delivery—ready to go work in your operation.

With the advanced capabilities of our BOBST 510 digital press, we deliver sharp detail, vibrant color, and consistent precision across every label. From white ink printing to variable data and multi-SKU runs, we're equipped to meet your toughest label demands.

More than 540 tons of paper are recycled every year through Buckeye's waste diversion program, reducing environmental impact.

Independent testing by Georgia Tech's Paper Science School verified that Buckeye's labels and release liners are fully recyclable and re-pulpable in the brown paper stream.

Our in-house hot melt adhesive uses clean electric heat instead of gas-fired ovens — cutting emissions and wasting less energy. For release liners, we use UV-cured silicone, enhanced with nitrogen for faster, high-quality curing.

By manufacturing without solvents, Buckeye avoids hazardous emissions and keeps production cleaner from start to finish.

We are investing in a new system that recirculates heated and cooled air back into the factory, reducing electricity and gas use. The air is also double-filtered, further improving quality throughout the facility.